The Evolution of Electronic Systems Technology and Its Impact on Methods of Innovation

Innovation is the creative development of a specific product, service, idea, environment, or process with the fundamental goal of pleasing customers and extracting value from its commercialization (Rogers, 2003; Oster, 2011). Purposeful differentiation must continue apace to avoid being overtaken by historically known competitors, as well as those who have yet to appear on corporate radar (Hamel, 2002). If the rate of change outside the organization exceeds that inside the company, survival is highly unlikely (Slater, 2004). In this decade, failure to address environmental pressures has caused thousands of companies to slash product development programs, reduce the size of the workforce, merge with other companies, or close down entirely. To survive and thrive in the hyper-competitive global marketplace, corporations, therefore, must produce a steady stream of innovation (Kelley, 2005). Every company is required to have a “pipeline” filled with upcoming innovation releases and must do everything within its power to abbreviate the time required for the development of new innovations.

The nature of innovation by modern product development teams and the opportunities facing next generation innovators can be understood through a close examination of the history of the modern cell phone and the associated advances in electronics technology. As electronic systems have become more complex, the elements within them have become more highly integrated in both functional and physical characteristics. These systems have evolved from large “boxy” structures with many discrete parts, to highly integrated structures with aesthetics designed to catch the eye of the consumer. Consider the evolution of the mobile phone from a large “box” in the trunk of a car into a modern, highly complex multi-function handheld cell phone. The increased complexity, packaging density, and functionality of modern cell phones is metaphorically representative of the change in the composition, skill mix, and tightly collaborative focus of the product development teams who innovate to create them. In fact, a comparison of the technologies used in a modern cell phone with those of the first generation mobile phone serves as a useful metaphor for exploring the changes in the nature and focus of innovation within the electronics industry over the past thirty to forty years. This evolution has resulted in innovations in new products, materials, computer-aided design tools, and manufacturing processes. With the rapid expansion of semiconductor technology and electronics packaging technology, entirely new design and manufacturing disciplines also have evolved. This has changed the nature and focus of innovation, significantly increasing the diversity of design teams and the need for collaboration across technical and business disciplines.

The Historical Evolution of Electronics and the Impact on Innovation

From the first patent issued to Alexander Graham Bell for the Telegraphy in 1876 (Inventors Hall of Fame, 2011), through the invention of the first handheld cell phone by John F. Mitchell of Motorola in 1973 (Absolute Astronomy, 2011), to the most modern personal cell phones of today, the nature of product innovation has taken on as many forms as the changes in the characteristics of the telephone. Product innovation throughout the electronics industry has evolved into a highly choreographed interdependence of technologies, materials, design methods, modeling tools, and manufacturing process development.

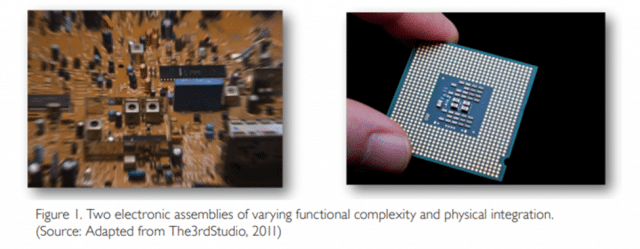

Consider the contrasting characteristics of the internal workings of multiple generations of electronic systems represented by the two distinctively different illustrations below. The figure on the left depicts an electronic circuit card assembly characteristic of electronic systems dating as far back as circa 1960 with the introduction of the first circuit board (Wagner, 1999). There are three distinct elements of this assembly: 1) the mechanical structure that houses the delicate electronics, protecting it from the ‘human’ environment (not shown in photo) (Karger & Murdick, 1980), 2) the (brown) printed circuit card, synthesized from epoxy glass or polyamide materials and metallic inner and outer layers, which provides the electrical and mechanical interconnection medium for the electronic components (Wagner, 1999), and 3) the discrete and varied electronic components that are mounted on the printed circuit card to create the electronic functionality of the system (Katz, 1977). The photograph on the right represents a highly integrated circuit known as a multi-chip module, typical of a modern cell phone, with much greater functional complexity than the circuit on the left. There are only two distinct physical elements of this assembly: 1) the highly integrated (gray and gold) mechanical and electrical package, synthesized from ceramic or plastic materials and metallic inner and outer layers, that now provides both the housing to protect the electronics and the electrical and mechanical interconnection of the electronic components, and 2) highly monolithic semiconductors and discrete components that combine the functional capabilities of the early generation systems into much more densely integrated electronics (Leahy et al., 1994; Crafts, 1996; Tummula, 1999). The electronic systems of today use “highly integrated and lowcost packaging that can improve performance and reduce cost and size by about a factor of ten” (Tummula, 1999) over comparable printed circuit card assemblies illustrated in the figure on the left. The former distinctions between many of the individual functions are no longer physically discrete in the modern multi-chip module.

Remarkably, the structure of modern electronic packages and the electrically interconnecting printed circuits are monolithically combined in a manner analogous to the combination of sand, rebar, and stone that form to make cement. The rapid growth of cellular telephone systems was predicated upon the introduction of low-cost microprocessors and availability of digital switching (Kumar, 2004). Although the integrated circuit was invented in 1958 by Jack Kilby at Texas Instruments, it was more than two decades before the cellular telephone industry began its torrid growth (Farley, 2005). Preceded by an extended period of dominance by landline telephone technology, cellular telephone systems represented a major threat to the established industry. Product innovation, process innovation, market characteristics, the competitive environment, and organizational change progress methodically with the establishment of a dominant design, and stabilize or slow in their rate of change with the length of time a dominant design satisfies the needs and wants of the consumer (Utterback,1994). The introduction of these new semiconductor technologies, and the associated wireless architectures they enabled, represented “the invasion of a stable business by radical innovation” (Utterback, 1996) to the telephone industry. The extensive delay in the introduction of cell phone technologies throughout the U.S. market was caused by bureaucratic challenges, non-stop lawsuits by the major phone companies attempting to protect their major landline investments, and independent radio common carriers and their suppliers who sought an equal playing field.

During this period of nearly forty years, the numerous disciplines required to transform the telephone industry, the skills needed to develop a modern electronic systems product, the complexity and sophistication of the modeling tools, the variety of the materials used, and the physical and functional complexity of the product have changed significantly. The introduction of these technological advancements into the telephone industry represented a radical departure from the dominant design architecture of the landline telephone systems, requiring a multidimensional effort of diverse teams to transform the telephony industry. The physical and functional changes of the electronics that enabled this transformation required different forms of innovation by electronics product development teams. This illustration reflects not only the growth in functional and physical integration of modern electronic systems, but also mirrors higher levels of collaboration within the product development team and their coordination across business development, marketing and sales, and legal teams to innovate at multiple dimensions of the product development and deployment.

The Changing Focus and Methods of Innovation within a Product Development Team

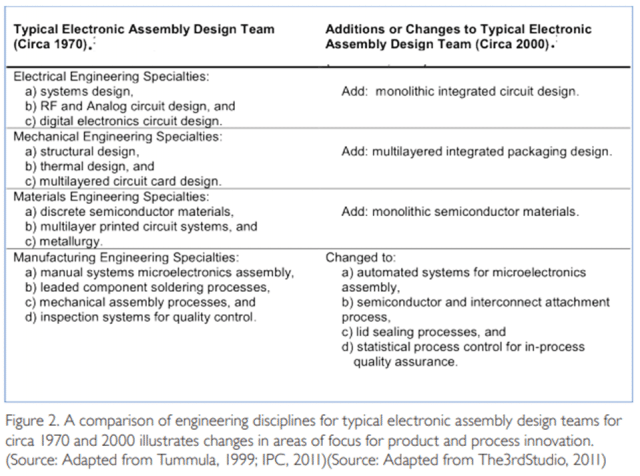

A typical circa 1970 design team, responsible for the development of an electronic assembly, would be comprised of an array of electrical, mechanical, materials, and manufacturing engineering disciplines. Within each of these professions, the team also would include specialists in a wide range of areas, as illustrated in the first column of Figure 2 below. New design disciplines were developed as the complexity of these electronic systems evolved. This increased the multidisciplinary nature and composition of the design team, reflected by the additions and changes to the design disciplines shown in the second column in Figure 2, enabling the additional complexity of product and process innovations.

The skills reflected in these two examples provide evidence of the change in focus for successful innovation within modern product development teams.

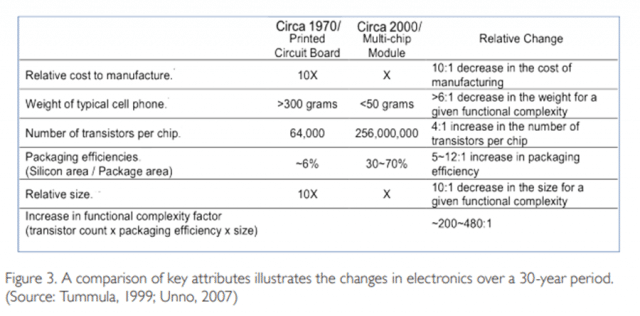

Even more exciting is the increased level of interdependency of design activities over this nearly forty-year period of technological development. To further understand the nature of this higher degree of collaborative interdependency, consider the characterization of electronic systems in Figure 3 below. This comparison, over the period of approximately thirty years, shows an increase in functional complexity of an electronics assembly ranging from 200 to nearly 500 times, with an associated tenfold cost reduction!

This is due to the increased levels of integration of packaging and semiconductor systems, enabling the more ‘monolithic’ assembly of modern electronics and higher use of automated production. These very characteristics reflect the radical nature of the threat presented to the landline telephone industry when implemented in the new wireless architecture.

This evolution resulted, in part, from the aforementioned design disciplines working in a much more collaborative fashion than ever before. Electrical systems engineers today must understand and coordinate a wider range of engineering disciplines to balance electrical requirements than their counterparts of yesteryear (Bevan & Romenesko, 1999). Electrical and mechanical specialists must collaborate in the complex design of highly functional and physically integrated monolithic semiconductor and packaging circuitry (Bevan & Romenesko, 1999). Mechanical and electrical engineers also must develop highly integrated models of structural, thermal, and electrical properties of a packaging design (Bevan & Romenesko, 1999). Finally, materials and manufacturing engineers must work closely with electrical and mechanical engineers in the design of new materials systems and associated manufacturing processes, well in advance of the completion of a design, to ensure the manufacturability of a balanced affordable product (Yang & El-Haik, 2009). These and many other collaborative activities are more complex and interdependent than similar activities for the circa 1970 design team.

The Globalization of Development and Production

The development and production of new products often occur simultaneously in a number of countries worldwide. Engineering staff need significant training and experience in working across borders of geography, languages, cultures, leadership models, and habits (McCall, 2002). In a global marketplace where the advantages of knowledge dissipate rapidly, innovation becomes even more important (Skarzynski, 2008). Unfortunately, there is currently a significant shortage of leaders and regular employees who possess international exposure and experience (Black, 1999; Rosen, 2000).

In addition to enabling work with a diverse team scattered around the world, intentional diversity is important in domestic operations. True diversity includes age, race, country of origin, experience, gender, education, etc. Innovative institutions especially look for “T-shaped people” (Kelly, 2005). Their primary skill (the vertical part of the “T”) is deep and technically expert, but they also harbor many additional interests and experiences (the horizontal part of the “T”) that help them to engage with others and consider a broad range of possible options. Insatiably curious amateurs often are preferred over bored narrow subject-area experts (Oster, 2011). In addition to diverse capabilities, employees also must have diverse attitudes (Bennis & Biederman, 1997; Hamel, 2002), with the ability to work across disciplines outside their individual areas of expertise and organizations. The ability and willingness to understand and capitalize on the diverse perspective that comes from this cross-disciplined collaboration has proven to be an underpinning of innovative organizations (Gryskiewicz, 1999).

Implications for Future Innovation throughout the Electronics Industry

Author and researcher Dr. Rao Tummula highlighted the increased importance of electronic packaging in our modern world (Tummula, 1999). The ever-increasing demand for consumer electronics has resulted in significant growth in this industry. Tummula suggests that product development engineers no longer have the time to learn on the job. They must commit to formal cross-disciplinary training throughout their careers to remain effective as innovators in this complex discipline (Tummula, 1999), well beyond the conventional training characteristics of heritage scientific and engineering disciplines. The results of a survey of the electronics industry, taken by the Georgia Institute of Technology Packaging Research Center (Tummula, 1999), suggest a wide range of educational needs for our next generation of electronics product development engineers. Classical training at most universities in “fundamentals of engineering,” “cross-disciplinary training,” and “fundamental science” will no longer be adequate (Tummula, 1999). Indeed, the recent records of many widely respected and historically innovative U.S. companies lack examples of new product lines and business generation, often due to absence of updated institutional learning (Lynn, Morone, & Paulson, 1996). The coming two decades will see an even more rapid convergence of biotechnology, materials science (including nanotechnology), artificial intelligence, robotics, computing, entertainment, and telecommunications (Lacohee, Wakeford, & Pearson, 2003). Product development engineers of today need expanded training to include: “knowledge of manufacturing processes,” “communication skills,” “management skills,” “business economics,” “foreign language and culture,” and “global markets” (Tummula, 1999).

Of even more importance is the requisite change in relationship between producer and prospective customer. Every innovative idea must focus on the needs and experience of customers. Because the ultimate goal of innovation is to effectively satisfy human needs and wants, new methods to ascertain their spoken and unrecognized requirements must be implemented (Nonaka, 1991; Hamel, 2002; Davila, et al., 2006; May, 2007). Using empathic study based on firsthand observation of and communication with customers, relations are developed that reveal their life frustrations and the products, services, ideas, environments, and processes that meet those realized and unarticulated needs (Brown, 2005; Christenson, 2005; Hagel, 2005; Lojacono & Zaccai, 2005; Suri, 2006).

A wider range of skills, complementing the specialization skills identified in Figure 2 above, suggest rich opportunity for highly-collaborative innovation by future product development engineers and their counterparts in global business and marketing development. They also suggest innovation that goes beyond the now classical multidisciplinary product development team. Engineers today and in the future not only will collaborate across engineering specialties; their collaboration will extend across both engineering and business cultures in a new global marketplace to realize new forms of product and process innovations.

Concluding Thoughts

Global business is experiencing change and upheaval as never before. Reviewing the changes that have occurred in one industry, cellular telephones, serves as a helpful metaphor for change in most other industries. As change continues, employees will need continual education and new skills to help them adjust to the everchanging environment. Skills enlargement, including capabilities previously possessed only by corporate executives, will be necessary for employees to function in the volatile global economy. Only those equipped and motivated to make nonlinear changes will survive the decidedly nonlinear future ahead.

About the Authors

Kevin Leahy is a doctoral student studying strategic leadership with the School of Business & Leadership, Regent University.

Dr. Gary Oster is professor of innovation and entrepreneurship at the Regent University School of Business & Leadership.

Notes

Bennis, W., & Biederman, P. (1997). Organizing genius. Addison-Wesley, New York.

Bevan, M., & Romenesko, B. (1999). Modern electronic packaging technology. Johns Hopkins APL Technical Digest. 22-33.

Black, J., Morrison, A., & Gregersen, H. (1999). Global explorers. New York: Routledge. Brown, T. (2005). Strategy by design. Fast Company, 52-54.

Brown, T. (2008). Design thinking. Harvard Business Review, 86(6), 84-92. Christenson, C. (2005). The innovator’s dilemma. Collins Business Essentials, New York.

Coughlan, P., & Prokopoff, I. (2004). Managing change, by design. In R. Boland Jr. and F. Collopy (Eds.), Managing as Designing (pp. 188-192). Stanford Business Books, San Francisco.

Crafts, H. (1996). Multi-chip module packaging system. U.S. Patent Number 5,497,027.

Davila, T., Epstein, M., & Shelton, R. (2006). Making innovation work. Wharton School Publishing, Upper Saddle River, NJ.

Farley, T. (2005). Mobile telephone history. Telektronic, 3(4), 22-34.

Gryskiewicz, S. (1999). Positive turbulence: Developing climate for creativity, innovation, and renewal. San Francisco: Jossey Bass.

Hagel, J., & Brown, J. (2005). The only sustainable edge. Harvard Business School Press, Boston. Hamel, G. (2002). Leading the revolution. Plume, New York.

History of mobile phones: Facts, discussion forum and encyclopedia article. (2011). Retrieved from: http://www absoluteastronomy.com/topics/History_of_mobile_phones

Inventor profile: Alexander Graham Bell. (n.d.). Retrieved from: http://www.invent.org./hall_of_fame/11.html IPC (2011). IPC’s PCB advanced designer certification: Workshop and exam. IPC Association Connecting Electronics Industries. Retrieved from: http://dc.ipc.org

Karger, D., & Murdick, R. (1980). Managing engineering and research: The principles and problems of managing the planning, development and execution of engineering and research activities. NY: Industrial Press.

Katz, G. (1977). Method of assembling components on printed circuit boards. U.S. Patent 4,113,524.

Kelley, T. (2001). The art of innovation. Currency Doubleday, New York.

Kelley, T. (2005). The ten faces of innovation. Currency Doubleday, New York.

Kumar, S. (2004). Mobile communications: Global trends in the 21st century. International Journal of Mobile Communication, 2(1), 67-86.

Lacohee, H., Wakeford, N., & Pearson, I. (2003). A social history of the mobile telephone with a view of its future, BT Technology Journal, 21(3), 203-211.

Leahy, K., et al. (1994). Packaging system for a standard electronic module. U.S. Patent 5,359,488.

Lojacono, G., & Zaccai, G. (2005, Winter). The evolution of the design-inspired enterprise. Rotman Magazine, 10–15.

Lynn, G., Morone, J., & Paulson, A. (1996). Marketing and discontinuous innovation: The probe and learn process. California Management Review, 38(3), 9-37.

May, M. (2007). The elegant solution. Free Press, New York.

McCall, M., & Hollenbeck, G. (2002). Developing global executives. Boston: Harvard Business School Press.

Nonaka, I. (1991). The knowledge-creating company. Harvard Business Review, 69(6), 96-104.

Oster, G. (2011). The light prize: Perspectives on Christian innovation. Virginia Beach, VA: Positive Signs Media.

Rogers, E. (2003). Diffusion of innovations (5th ed.), Free Press, New York.

Rosen, R. (2000). Global literacies. Simon and Schuster, New York.

Schrage, M. (2000). Serious play. Harvard Business School Press, Boston.

Schwartz, E. (2004). Juice: The creative fuel that drives world-class inventors. Harvard Business School Press, Boston.

Skarzynski, P., & Gibson, R. (2008). Innovation to the core. Boston: Harvard Business Press. Slater, R. (2004). Jack Welch on leadership. McGraw-Hill, New York.

Suri, J. (2006, Winter). Informing our intuition: Design research for radical innovation. Rotman Magazine, 52–57.

Tummula, R. (1999). Electronic packaging research and education: A model for the 21st century. Johns Hopkins APL Technical Digest. 111-121.

Unno, Y. (2007). High-density low-mass hybrid and associated technologies. High Energy Accelerator Research Organization (KEK). 1-11. Used with permission by The3dStudio.com through “End User License Agreement,” 14 October, 2011.

Utterback, J. (1996). Mastering the dynamics of innovation. Harvard Business School Press, Boston.

Wagner, G. (1999). History of electronic packaging at APL: From the VT fuse to the NEAR Spacecraft. Johns Hopkins APL Technical Digest. 7-21.

Yang, K., & El-Haik, B. (2009). Design for six sigma: A roadmap for product development (2nd ed.). [Books24x7 version] Retrieved from: http://common.books24x7.com